Root Piles

The Root Pile is a mortar pile "on site" and with high shaft working tension. It is mainly characterized by being a pile made with the use of coating, which allows to reach long lengths, in rock or soil.

With the use of small and medium sized equipment, Root Piles can be run in hard to reach places. The execution methodology of this pile does not cause vibrations, which allows it to be used in any industrial work situation. When it is necessary to cross boulders, concrete blocks or embed them in rock, the drilling is complemented with the use of a hydraulic hammer until reaching the desired depth. Geofix runs Root Piles up to Ø500mm and 52m deep according to the ground conditions.

Advantages

No vibration and ground decompression

Possibility to be performed in limited space areas

Can be used on geological terrains with presence of boulders, rocks and even concrete

EXECUTION METHODOLOGY AND IMPLEMENTATION CARE

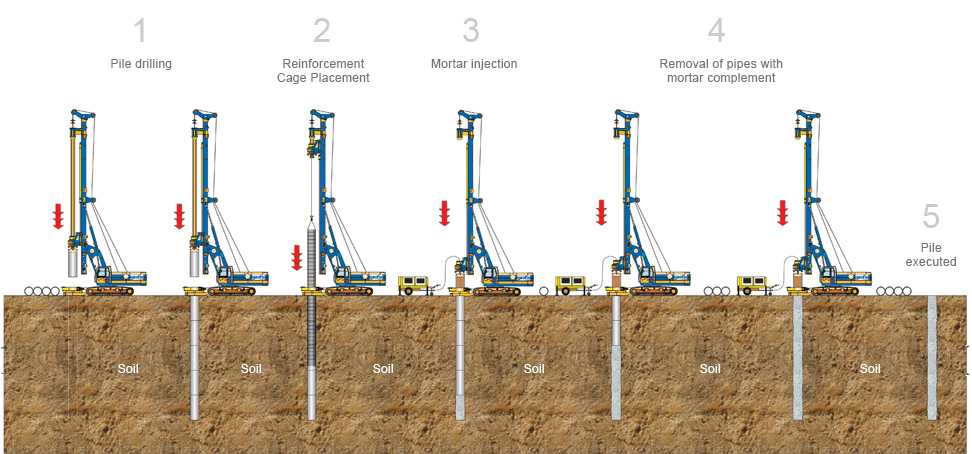

The execution of a root pile comprises the following sequence:

The drilling of the hole vertically or inclined is performed through appropriate mechanical equipment called drill rigs (hydraulic, mechanical or pneumatic).

The drilling is performed by rotating or percussion, with circulation of a fluid consisting of water or bentonite slurry in some special cases, with the introduction into the ground of threaded steel tubular elements at the end of which there is a special crown with high cutting power.

The circulation fluid flow that carries drilling waste occurs on the outside of the coating, making the hole larger in diameter than the diameter of the drilling pipes used within the drilling process.

As the drilling continues, the drill pipe penetrates the ground and the various segments are joined together by threaded joints.

The drilling continues until the limit is achieved, according to the project.

When the drilling is complete, and if bentonite slurry has been used, a water wash should be applied to completely remove this material used. After this, a steel reinforcement cage is placed inside the drill pipe. This structure can be formed by one or more beam-mounted bars, or through cages as specified by the structural design of the pile.

A drill pipe reaches out the bottom and through this pipe is injected the mortar (cement and sand), prepared in a high turbulence mixer. The mortar injection is processed from the bottom up, producing a displacement of the existing water in the hole.

This operation is carried out with the hole fully coated with the drill pipe. Therefore, it is performed with maximum safety for continuity of the pile shaft.

When the drill pipe is completely filled with mortar, its upper end is buffered and a pressure with compressed air is applied.

The pressure applied to the mortar depends on how the ground will absorb this mortar and must be at least 4.0kgf / cm².

This pressure enables the mortar to penetrate the ground, significantly increasing the lateral friction and ensuring the continuity of the shaft.

The withdrawal of the drill pipes begins through hydraulic jacks and as the sections of pipe elements are being removed, a complementation of the mortar level inside the pipe occurs, with the application of a new pressure. This procedure continues until the pile shaft is fully completed by the removal of all drill pipes.

See other

services