Slurry Wall with Clamshell and / or Hydromill

They are curtains executed and filled with reinforced concrete, after the excavation of trenches (lamellas) opened in the ground and kept stable with the aid of bentonite slurry or polymer.

Geofix performs electronic monitoring in the execution process to control the verticality and positioning of the excavation with the use of Hydraulic Clamshell. This process renovated the excavation and foundation technique and can be used in:

Elements of water and soil containment (rigid diaphragms), on temporary or permanent excavations as roads, buried or semi-buried stations and galleries, building basements, pump houses, turbines or reactors, port works, dams, dikes and locks. In addition to the containment function, the walls can also receive vertical loads.

Waterproofing elements (plastic diaphragms), aimed at controlling the percolation of excavations in contaminated soils, dikes, dams and reservoirs.

Foundation elements (Diaphragm Pile), transmitting loads to deeper layers. The development of excavation equipment, ecological slurry processing plants with recyclers, allowing total reuse of the slurry without disposal, are key advances which assure great service sustainability.

The development of excavation equipment, in conjunction with the ecological processing plants for bentonite slurry through the “Reciclador and Floculador*” system, made possible a new advance in the sustainability of this service, as a result of the slurry re-enhancement and reduction in water consumption.

Advantages

Execution without vibrations and noise when driving foundation piles or shoring.

Possibility to pass through layers of great resistance.

As support elements for excavations, the walls have great resistance and little deformability, which makes them the most suitable solution for supporting excavations close to existing buildings.

Frequently more economical due to the incorporation of the walls into the permanent structure.

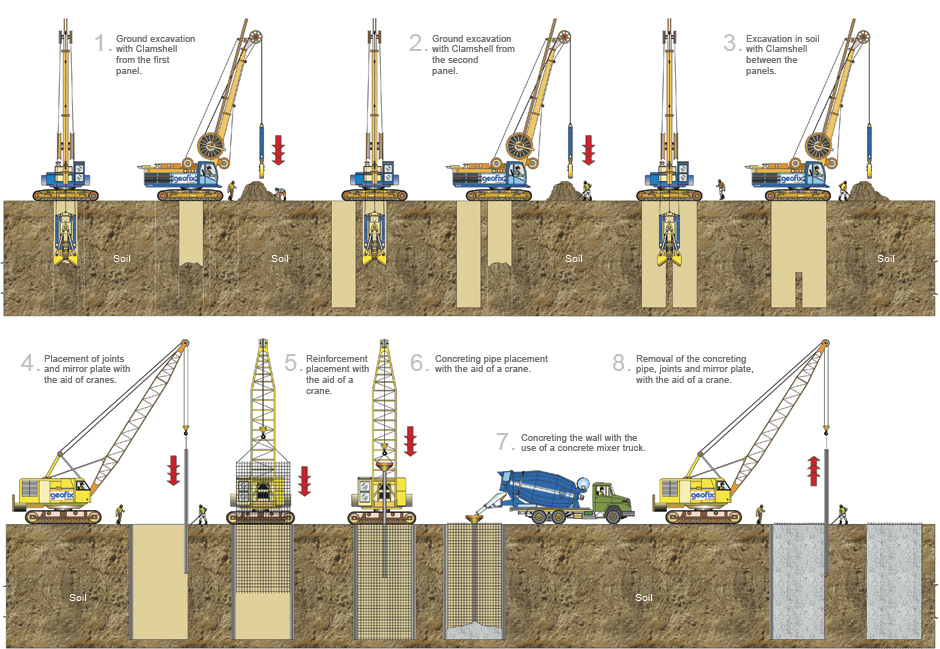

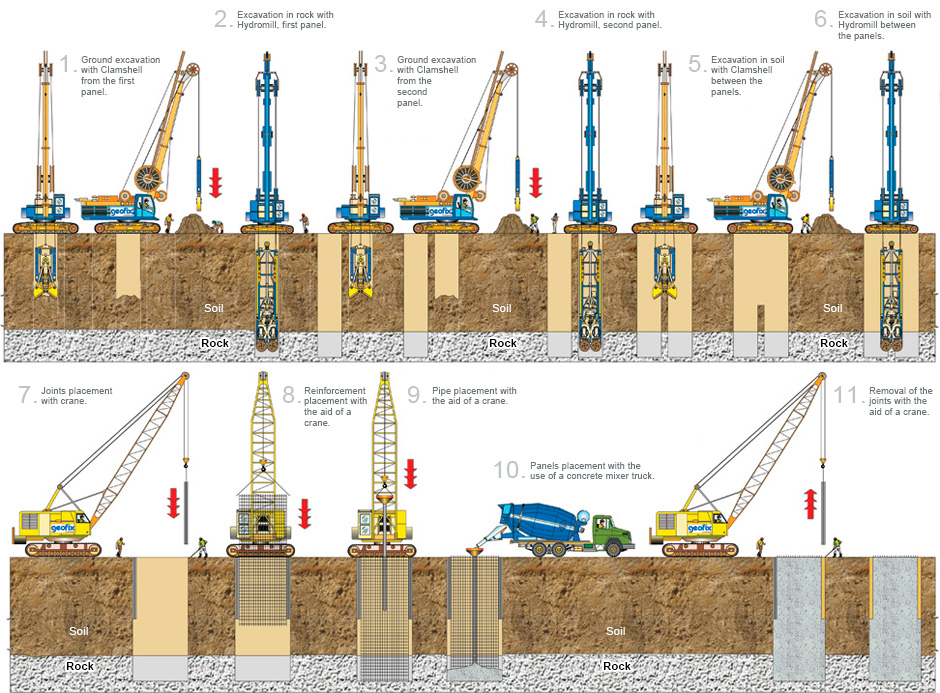

EXECUTION METHODOLOGY AND CARE IMPLEMENTATION

Execution Phases

For the execution of the diaphragm wall, several actions are carried out that are interconnected and each one must be planned in advance so that there are no unforeseen events.

We can highlight the following well-defined phases, namely:

a) Execution of the guide wall.

b) Slurry manufacturing.

c) Excavation.

d) Slurry exchange.

e) Reinforcement placement.

f) Concreting.

Execution of the Guide Wall

The execution of the diaphragm wall is preceded by the execution of guide walls, which aims to:

• Determine the wall path, serving as a guide for the excavation tool, clamshell.

• Prevent the soil collapse close to the surface due to the large and permanent variation in the level of mud and the entry and exit of the clamshell during excavation.

• Ensure a mud height compatible with the water table level (h = 2.00m).

See other

services